Introduction: The Challenges Posed by Traditional Gripping Technologies

Imagine working on an assembly line where items need to be gripped and moved with precision while ensuring minimal errors. Data indicates that over 30% of production disruptions are linked to faulty gripping mechanisms. The electric gripper has emerged as a highly effective solution to address these challenges. This transformative technology not only enhances performance but also improves operational reliability, thereby reducing overhead costs and downtimes.

Body: Understanding Electric Grippers

Traditional Solutions and Their Flaws

Most conventional gripping systems rely on pneumatic or mechanical means. Here’s the catch—these methods often lead to inconsistencies, lack of flexibility, and high maintenance demands. Pneumatic systems, for instance, require a constant supply of air and can be affected by temperature fluctuations, resulting in inefficiencies. This is the reason many industries are turning to electric solutions for enhanced reliability.

The Principles Behind Electric Grippers

Electric grippers operate on the principle of linear actuators—utilizing electric motors to control movement. By leveraging advanced algorithms, these devices can easily adapt to various materials and shapes. The integration of sensors and edge computing nodes allows real-time feedback, making each gripping action precise. This innovative technology translates to increased productivity and reduces the likelihood of product damage during handling.

Quantified User Benefits

Users of electric grippers report up to a 50% improvement in operational efficiency. The elimination of pneumatic systems lowers energy costs and requires minimal maintenance, leading to a significant decrease in overall expenses. Moreover, the versatility of electric grippers enables seamless integration into existing automation systems, making them a crucial investment for future-proofing operations.

Conclusion: Criteria for Evaluating Gripping Solutions

When considering solutions for gripping tasks, it’s essential to evaluate these three metrics: ① operational efficiency ② reliability and maintenance costs ③ adaptability to diverse applications. A well-rounded assessment will help you choose an electric gripper that fits your specific needs and enhances your production capabilities.

The Electric Gripper Actuator: Definition and Importance

The electric gripper actuator is an essential component designed to facilitate precise movements and grip actions. Unlike traditional actuators, electric models provide enhanced torque and control, making them ideal for automation processes. By minimizing inconsistencies, they ensure that products are handled properly, reducing waste and enhancing overall productivity. Moreover, the integration of advanced control systems in electric gripper actuators leads to real-time adaptability, allowing them to function effectively in dynamic industrial environments.

Advantages of Using Electric Grippers in Automation

Electric grippers are gaining traction due to their flexibility and reliability. These electric grippers can handle a variety of shapes and weights, responding dynamically to the needs of different applications. Their compatibility with existing robotic systems allows for a smooth transition from traditional gripping methods, which often suffer from limited versatility. Additionally, the integration of smart technologies enables enhanced data analytics and machine learning capabilities, giving users insights into operational efficiencies that can lead to significant improvements in performance and cost-effectiveness.

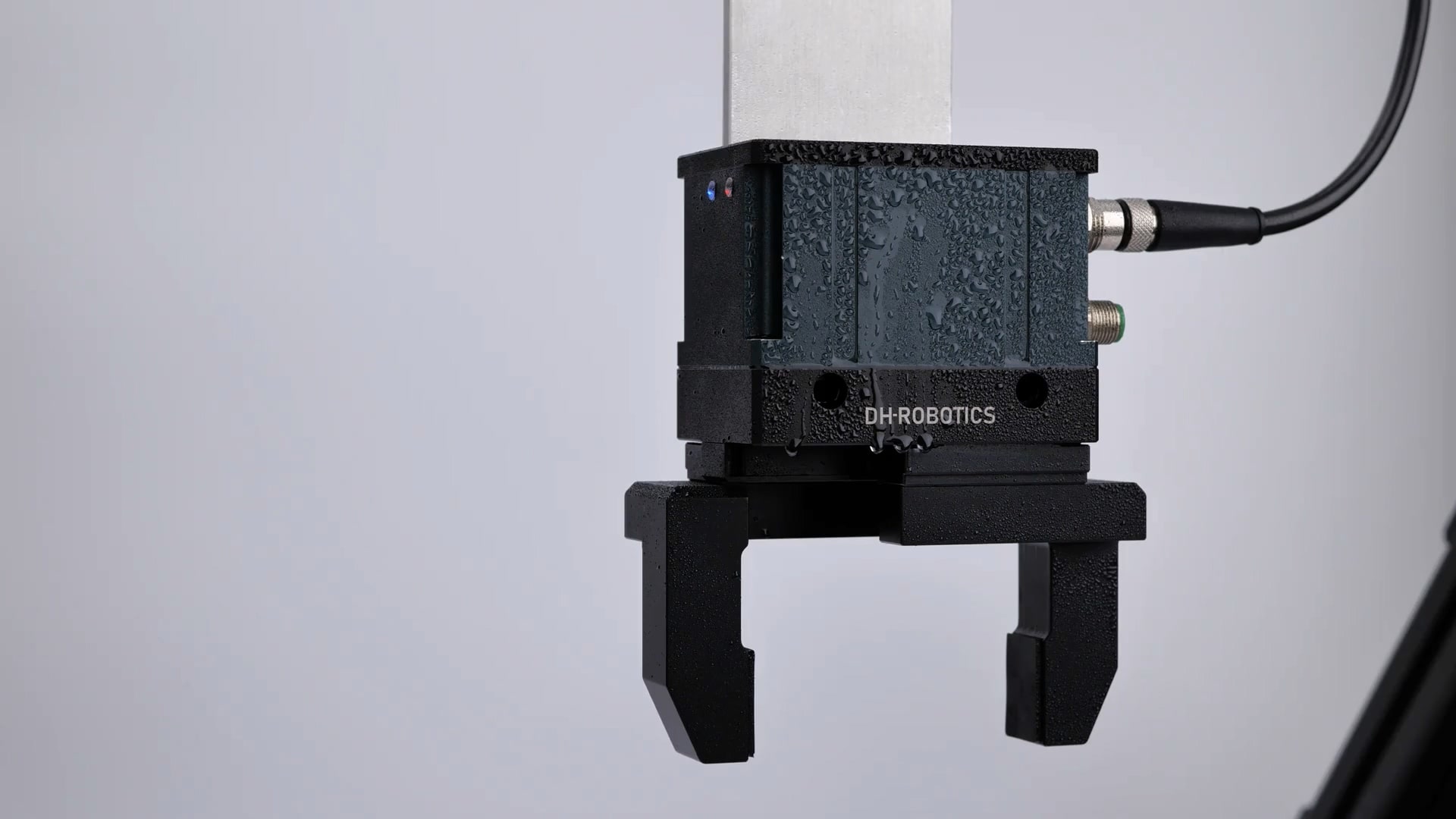

In summary, the integration of electric grippers and their actuators into automation systems represents a significant advancement in industrial technology. For businesses looking to enhance operational efficiency and reliability, DH-Robotics stands out as a leading manufacturer, offering high-quality solutions that come with supply advantages tailored to the needs of various industries.